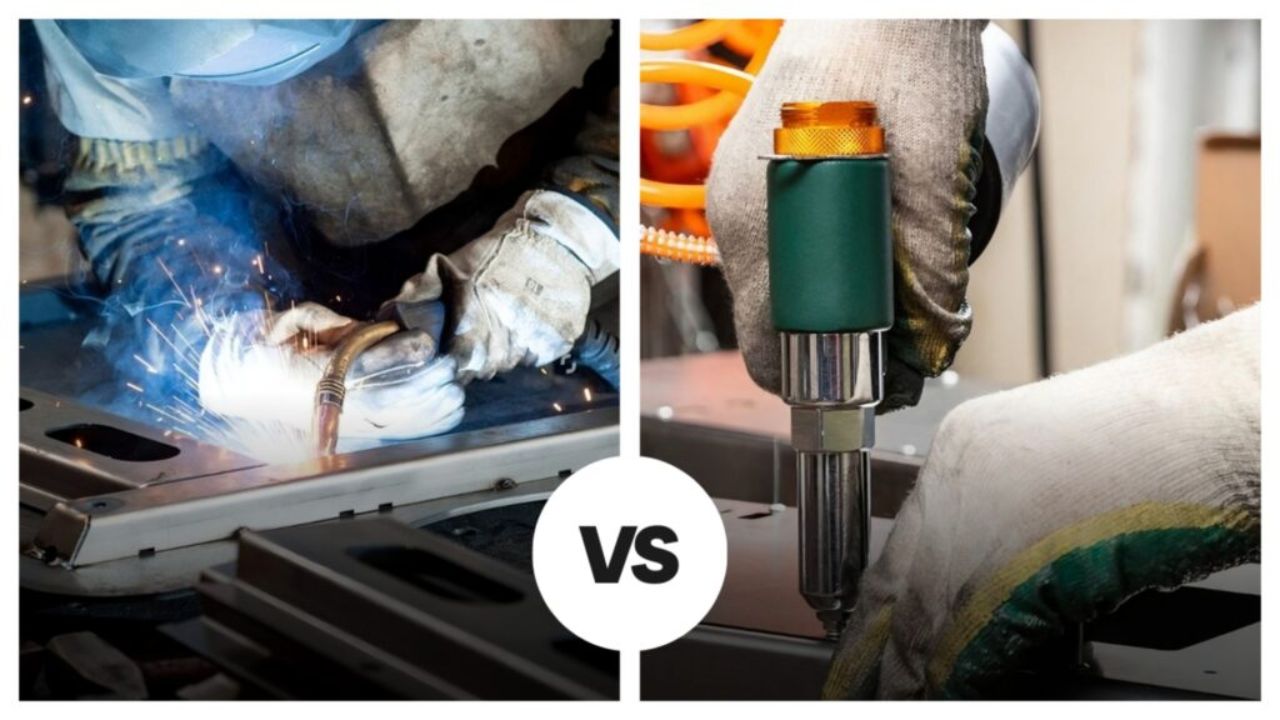

Choosing Between Welding and Riveting in Modern Metal Fabrication

With contemporary metal fabrication, joinery can have a great influence on the performance in terms of strength, appearance, cost and long-term performance of two metal body parts. Welding and riveting are some of the most common techniques of joining. These two techniques are quite old in the manufacturing industry, but both are still essential in the advanced fabrication projects in the current world. The aim of a choice between welding and riveting does not consist in which process is all-embracing good, but in which one is more appropriate to the material, use, and production demands.

Understanding Welding in Fabrication

Welding is the process of metalworking whereby the edges are melted and joined together, and in many cases, a filler metal is added. When chilled, the joint is one continuous piece of metal. The technique has found its application in structural applications where great strength and rigidity are necessary.

Modern fabrication also provides the possibility of precise control and consistency of results in the welding technologies of MIG, TIG, and laser welding. Welded joints have been appreciated in terms of their capability to support heavy loads, be leak-free, and produce smooth surfaces. The joint being made permanent makes welding a common choice with frames, pressure vessels and those components where disassembling is not a possibility.

Understanding Riveting in Fabrication

Riveting is a mechanical fastening process that connects metal components with the help of a rivet that is inserted through aligned holes and deformed to secure the materials. Riveting does not make use of heat, unlike welding, to form the joint. Rather, it employs a clamping force to hold the parts.

Riveting in the production of metal fabrication plays a critical role in modern day in particular where thin sheet metal and dissimilar materials are involved or in heat-sensitive components. Innovation of blind rivets and structural rivets has enhanced efficiency in strength and installations, and riveting will be used in both light and some structural applications. The riveted joints are also easily reworked or replaced as opposed to the welded joints.

Strength and Structural Performance

Welding can usually win when strength is the main consideration. With a correctly made weld, the strength of the base metal can be as strong or stronger and hence this can be used in load-bearing structures. Welded joints are inflexible, therefore, assisting in supporting alignment in heavy assemblies.

Although riveting is typically not as stiff as welding, it is strong in another form. The riveted joints also spread the stress among several fasteners and have some limited elasticity. This property enables rivets to be more resistant to fatigue and vibration in some uses, including transportation machinery and enclosures that undergo frequent movement.

Material Compatibility and Heat Effects

The kind of material to be used is a significant factor when determining whether to weld or rivet. Welding normally involves the use of matching metals, with dissimilar materials being challenging or ineffective to join. Also heat used in the welding process may result in warping, distortion, or even a modification in the material properties, particularly in thin sheet metals.

Riveting does not have the problems since it is a cold process. It enables joining of various metals, including aluminum and steel, without any impact on surface finishes and structural integrity. Riveting is usually the safest method of installation in the case of projects where the appearance and dimensional accuracy are important.

Cost, Skill, and Production Considerations

Welding is typically more expensive to initiate. The production costs include equipment, skilled labor, and safety measures. In high-volume or heavy-duty applications, however, the welding process may be economical because it is both durable and requires the minimum number of fasteners.

Riveting is less expensive to enter and less complex to learn. Some assemblies are easier to install and can be repaired more easily in case there is a need to make changes. Riveting can minimize risk and permit design changes without a great deal of material waste in prototyping or in low or high-volume production.

Conclusion

When it comes to modern metal fabrication, deciding on welding or riveting would be a matter of balancing strength, flexibility, material type, scale of production, and future usage. Welding is capable of permanently bonding high-strength joints that are rigid and require a seal. Riveting is also good in working with thin materials, mixed metals, vibration or easy rework.

Instead of considering welding and riveting as rival techniques, the established fabricators consider them complementary. With the knowledge of the pros and cons of each, manufacturers can choose the most efficient and reliable method of joining to use in every project, which is certain to make it high in quality, performance, and cost-effectiveness in recent fabrication.